Posted by

Easy WoodCraft on

Oct 24, 2016

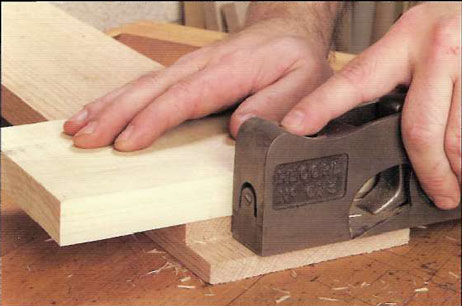

After a good jack plane and a low-angle block plane, the next plane I`d suggest a beginning woodworker purchase is a quality shoulder plane (

right photo). Shoulder planes excel at trimming and fine-tuning joints. They're great for trimming rabbets, shoulders, tenons, dadoes, and grooves. This is the tool to reach for when a joint just doesn't fit right and needs a "tweak" or two to get that perfect fit. Most shoulder planes are all-metal to help create a heavy, dense tool that can effectively prevent or dampen blade chatter.

The blade on a shoulder plane runs the full width of the body, and the sides and sole of the plane are ground at perfect right angles to each other (

left drawing).

Shoulder planes come in widths ranging from 1/2" to slightly over an inch. As on a block plane, the blade is mounted bevel-up and generally has an effective cutting angle of around 37 degrees. This makes it quite good at trimming end grain. Another thing that helps with trimming end grain and making fine cuts in general is an adjustable throat. On some planes this is adjustable by way of a screw; other planes require that you add or remove shims between the two halves of the body to vary the opening. The blade can be held in place a number of ways. On some larger planes, the blade is often held fast by a lever cap and a locking screw while others use a more traditional lever cap screw that requires a screwdriver. Smaller shoulder planes generally use a wedge and are adjusted like any wood-bodied plane: You tap on the front or rear of the body to lower or raise the blade.

Trimming tenons

My general rule of thumb for cutting mortise-and-tenon joints is to cut the mortise first and then cut the tenons to fit. If you're chopping the mortises by hand (

see Mortise Chisels), you'll likely find some variations from mortise to mortise. This means you'll have to trim or fine-tune each tenon to fit: a perfect job for the shoulder plane. Whenever possible, select a plane that's slightly wider than the area you're intending to trim. Make sure to set the plane for a very fine cut and use a razorsharp blade. As always, take light cuts and make sure to back up the shoulder with a scrap to prevent tear-out.

Smoothing rabbets

Smoothing rabbets is another easy task for a shoulder plane. Position the plane so the side of it butts firmly against the shoulder of the rabbet. Use as long a shoulder plane as possible, as this helps flatten out any high spots that a shorter-bodied plane might ride up and over. Just as with a tenon, it's important to back up the trailing edge of the rabbet with a scrap to prevent tear-out.

COMBINATION SHOULDER PLANES

There's a nifty type of shoulder plane available that's commonly called a combination plane. It's basically two planes in one: a shoulder plane and either a bull-nose plane (

see Bull-Nose Plane) or a chisel plane (

see Chisel Planes). The conversion from one to the other is made possible either by lifting off a top piece (

as shown here) or by removing a front section of the plane. Sometimes this type of plane is called a 3-in-1 plane because it can function as a shoulder plane, bull-nose plane, or chisel plane.

Cutting a rabbet

You'll occasionally hear a shoulder plane referred to as a rabbet plane. That's because it can be used very effectively for this task. The disadvantage to using a shoulder plane versus a rabbet plane is that the shoulder plane doesn't have a built-in guide fence or depth gauge. But one will work in a pinch as long as you clamp a scrap block to the work-piece to guide the cut, and check the depth often with a rule. Also, since a shoulder plane doesn't have cutting spurs, it's a good idea to scribe a starting line when planing cross grain.

Cleaning out a dado

Another job I often assign to a shoulder plane is cleaning out grooves or dadoes. Naturally it's best to use a shoulder plane that matches the width of the groove or dado, but you can usually get along just fine with a narrower one as long as you check the bottom for flatness often. Keep the side of the plane pressed firmly against the shoulders of the groove or dado as you plane.

BULL-NOSE PLANES

A bull-nose plane is a special type of shoulder plane that has a very short. Instead of a longer front section, the nose is often only ¼" wide. This makes the plane perfect for delicate work and for reaching in close to corners. The disadvantage to using a bull-nose plane: The short nose allows the plane to travel up and down over undulations instead of flattening them. If you find this happening, it's best to switch to a longer, standard shoulder plane.

Thanks for reading Shoulder Planes. Please share...!