If you haven't already tried one, Japanese saws are another one of those must try tools. Unlike Western saws, which cut on the push stroke, Japanese saws cut on the pull. Many woodworkers (including myself) feel that this affords better control. Also, because the blade is pulled through the cut, there's less chance of crimping the blade. This means the blades can be thinner, which results in a thinner kerf. The metal used for Japanese saws is harder and the teeth are tempered to a high degree. This keeps them sharper longer, but makes them almost impossible to resharpen. This isn't a negative, since the tooth geometry is complex (see

Bird's Mouth on Coping And Fret Saws), and with many of these you can replace the blade when it dulls).

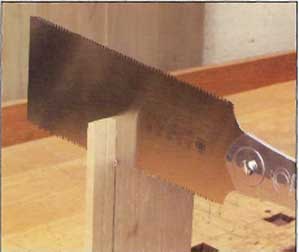

Dozuki

Of all the Japanese saws, the dozuki (pronounced

DOZE-oo-key) is my favorite. It's the Japanese equivalent of the Western back saw; and since I began cutting dovetails with one of these many years ago, it has earned a special place in my tool chest. Dozuki means "shoulder" in Japanese, and this saw was originally intended to cut the shoulders of a tenon. But I've found that this thin but rigid backed blade is perfect for almost any handcut joinery. Typically this saw has around 26 teeth per inch and can vary from 8" to 12" in length.

Ryoba

The ryoba saw (pronounced

Ree-OH-bah) is a terrific saw to have on hand, as it combines the functions of a Western crosscut and rip saw in one tool. Ryoba means "double" in Japanese, and this saw has cross teeth on one side of the blade and rip teeth on the other. These saws come in blade lengths varying from 7" to 13". The smaller saw works well for joinery and the larger versions are excellent for general purpose cutting.

Azebiki

The azebiki saw (pronounced

Eh-zeh-BEE-kee) is a special type of ryoba saw (crosscut teeth on one side, rip teeth on the other) that is designed specifically to make plunge cuts, such as a mortise or tenon in the center of a board. The blade is curved to let you easily start a cut in the middle of a work piece. Its diminutive size makes it handy for getting into places other saws can't. The curved blade also makes it easy for you to clear sawdust from the kerf by simply using a rocking motion as you cut.

Kugihiki

The kugihiki saw (pronounced

COO-gee-HEE-kee) is another specialty saw that you might find useful. In Japanese, kugihiki means "to cut nails," as in wooden nails or dowels. The super thin blade does not have a back like the dozuki, so it's extremely flexible, but also prone to kinking. And just as important, the teeth on this style saw have no set. This means that the blade can rest on a surface without scratching it. The downside to this is that binding can occur if you're removing a lot of wood, such as when cutting off a through tenon.

TOOTH PROFILES

If you examined the teeth of a Japanese saw with a magnifying lens, you'd find a complex tooth geometry the teeth are longer and thinner and have more faceted surfaces than Western-style teeth. This is particularly true of the crosscut teeth. Unless you're willing to devote many hours to practicing sharpening these complex grinds, I suggest sticking with saws that have replaceable blades.

CHECKING FOR DRIFT

You've just bought a new back saw or dovetail saw, and after making a couple of test cuts, you notice they aren't straight. Is it you or the saw? Quite often it's the saw. In many cases the set of the teeth is too aggressive or not even. When this occurs, the saw tends to drift one way or the other. To eliminate this, use the procedure below.

Cut a kerf

Start by making a test cut in a scrap of wood. Hold the saw lightly, and don't try to compensate if it starts to drift off course. Let it make its own kerf.

Check for drift

Next, remove the saw from the kerf and check the kerf with a square. Any deviation means that the teeth on one side either are set more aggressively or are sharper than the other side. This is also a good time to check for the overall set. Insert the blade back in the kerf and try to wiggle it; if there's a lot of slop, the set is too aggressive.

Correct the problem

To reduce the set on one side of the saw, use an oilstone. Set the saw on a flat surface and add a drop or two of honing oil to the stone and rub it gently over the teeth. If the overall set is too aggressive, do this to both sides, taking the same number of strokes per side. Take just a few strokes with the oilstone and make another test cut. Repeat as necessary until the saw no longer drifts and the blade doesn't wobble in the kerf.